#Overview

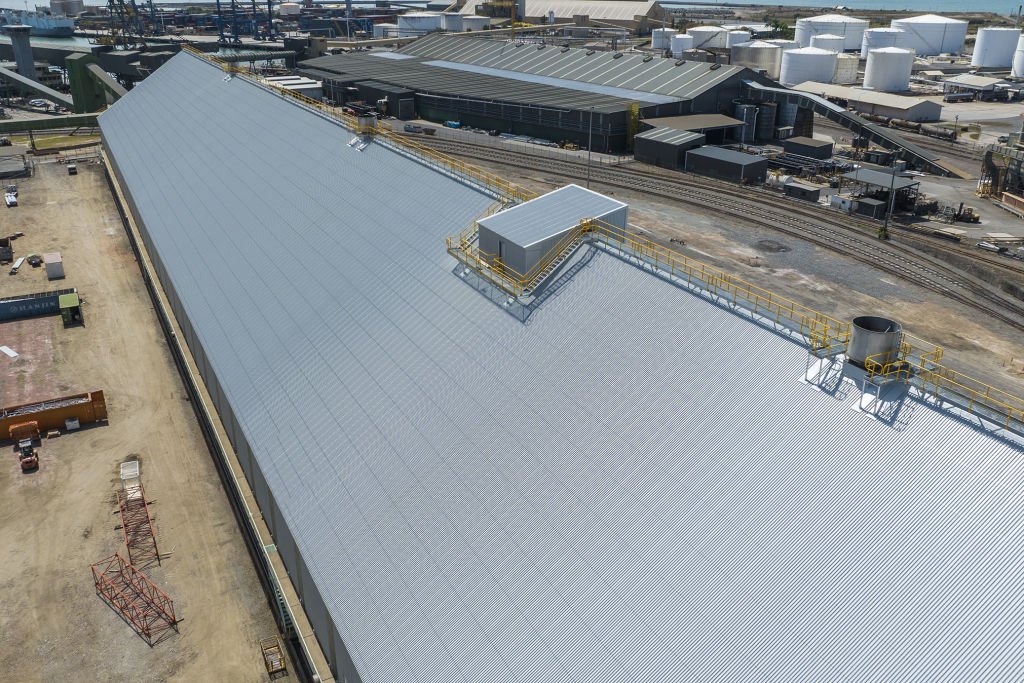

BESIX Watpac delivered the roof replacement for Shed 1 and Shed 2 at the Townsville Bulk Sugar Terminal, installing new aluminium cladding and upgrading structural steel elements including roof purlins, trusses, end walls, and roller doors. The sheds make up critical infrastructure for Queensland’s sugar industry and are a key part of the Townsville Bulk Sugar Terminal.

Given the high-risk nature of the works – particularly working on a roof with a 34-degree pitch—the project team adopted a relatively new but proven safety innovation. This involved the use of ‘roof walker’ technology, featuring a rolling platform that enabled workers to operate safely and efficiently.

#Details

415

Tonnes of roof sheeting

2

Bulk storage sugar sheds

40

Year extended lifespan

#Delivery

- This project has extended the life of Townsville’s sugar export infrastructure by at least 40 years

- Works involve high-risk activities including asbestos removal and working at heights on a 34-degree pitch roof within an operational terminal

- Construction is coordinated with STL’s safety plan to ensure safe terminal operations

- Delivery was scheduled around the cane crushing season to minimise disruption

- Programming accounted for project-specific risks such as inclement and windy weather, ensuring safe and efficient execution throughout the construction period

"On a roof with 35 degrees pitch, safety was paramount. We deployed an innovative system to ensure worker safety. This system utilised a rolling platform which travelled along the purlins and provided a safe platform for workers to operate."

Wade Cummins, General Manager – QLD, NT & NZ, BESIX Watpac

Industrial

Military Vehicle Centre of Excellence

Industrial